Rolling Coupler

16-32mm

Choose from a wide range of Rolling and Forging Couplers, precision-manufactured for high-strength connections in TMT bars.

16-32mm

20-40mm

Custom Sizes

| Coupler Type | Description |

|---|---|

| Rolling Coupler | Used for standard splicing with parallel threads. Suitable for fast & uniform jobs. |

| Forging Coupler | Ideal for heavy-duty structural connections. Enhanced strength & load-bearing. |

Both types are available with on-site threading & forging service for direct installation.

| TMT Bar Size (mm) | Outer Diameter (mm) | Coupler Length (mm) | Thread Pitch (mm) |

|---|---|---|---|

| 16 mm | 25 mm | 40 mm | 18 x 2.5 |

| 20 mm | 32 mm | 54 mm | 23 x 2.5 |

| 25 mm | 42 mm | 64 mm | 29 x 3.0 |

| 32 mm | 50 mm | 78 mm | 35 x 3.0 |

| Custom Available | As per project need | As per threading |

Parallel Metric Thread

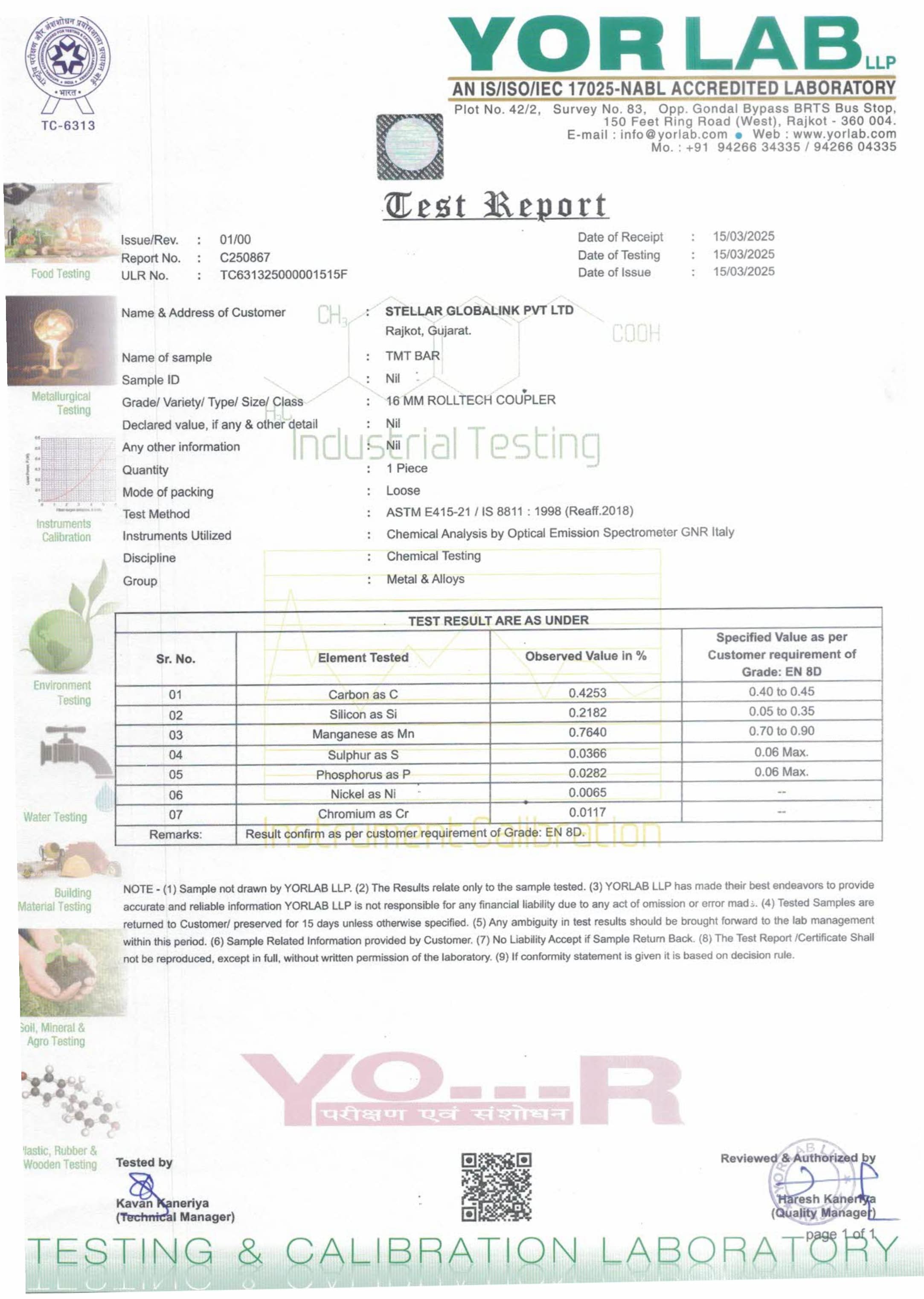

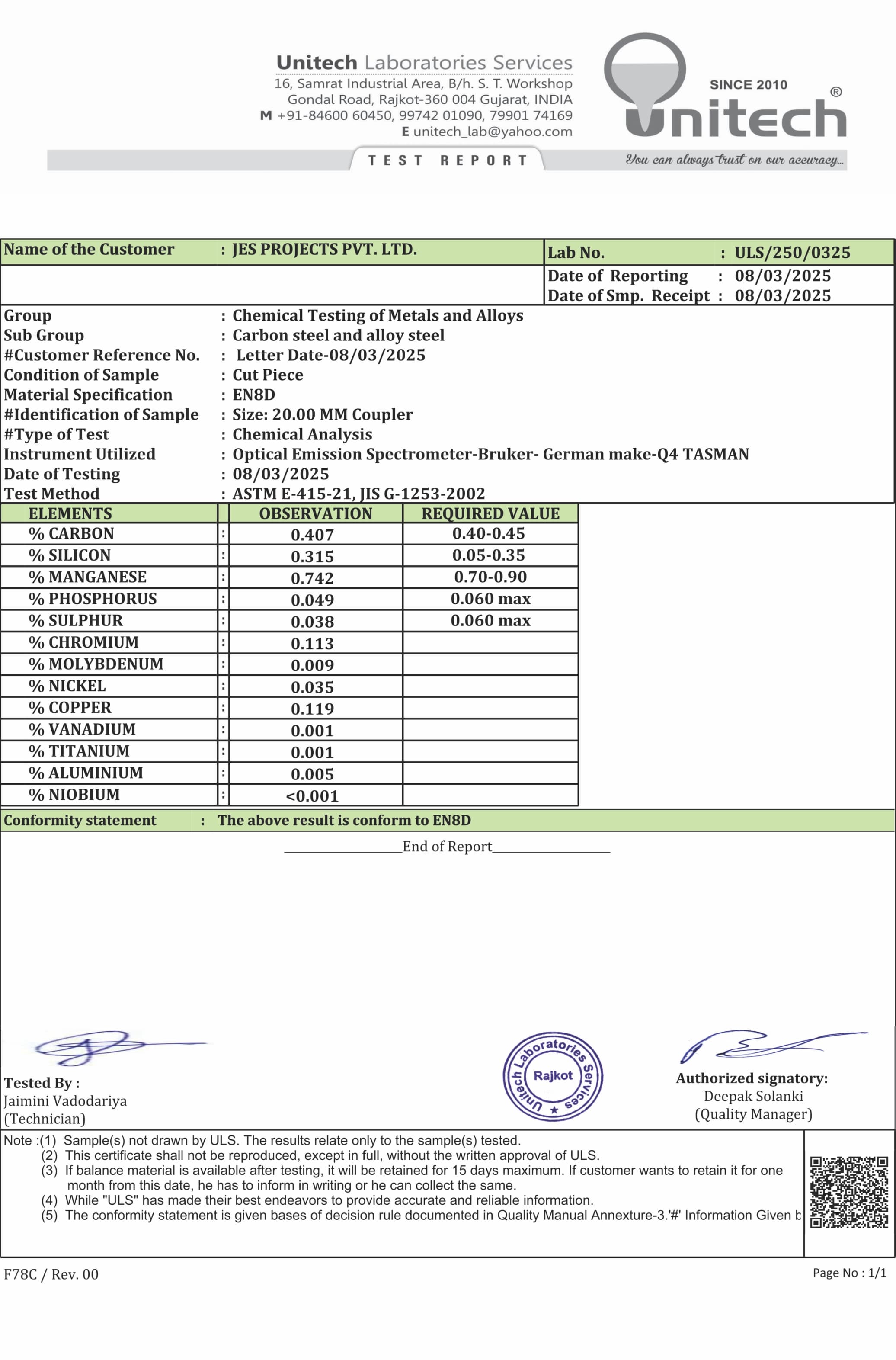

EN8D Steel

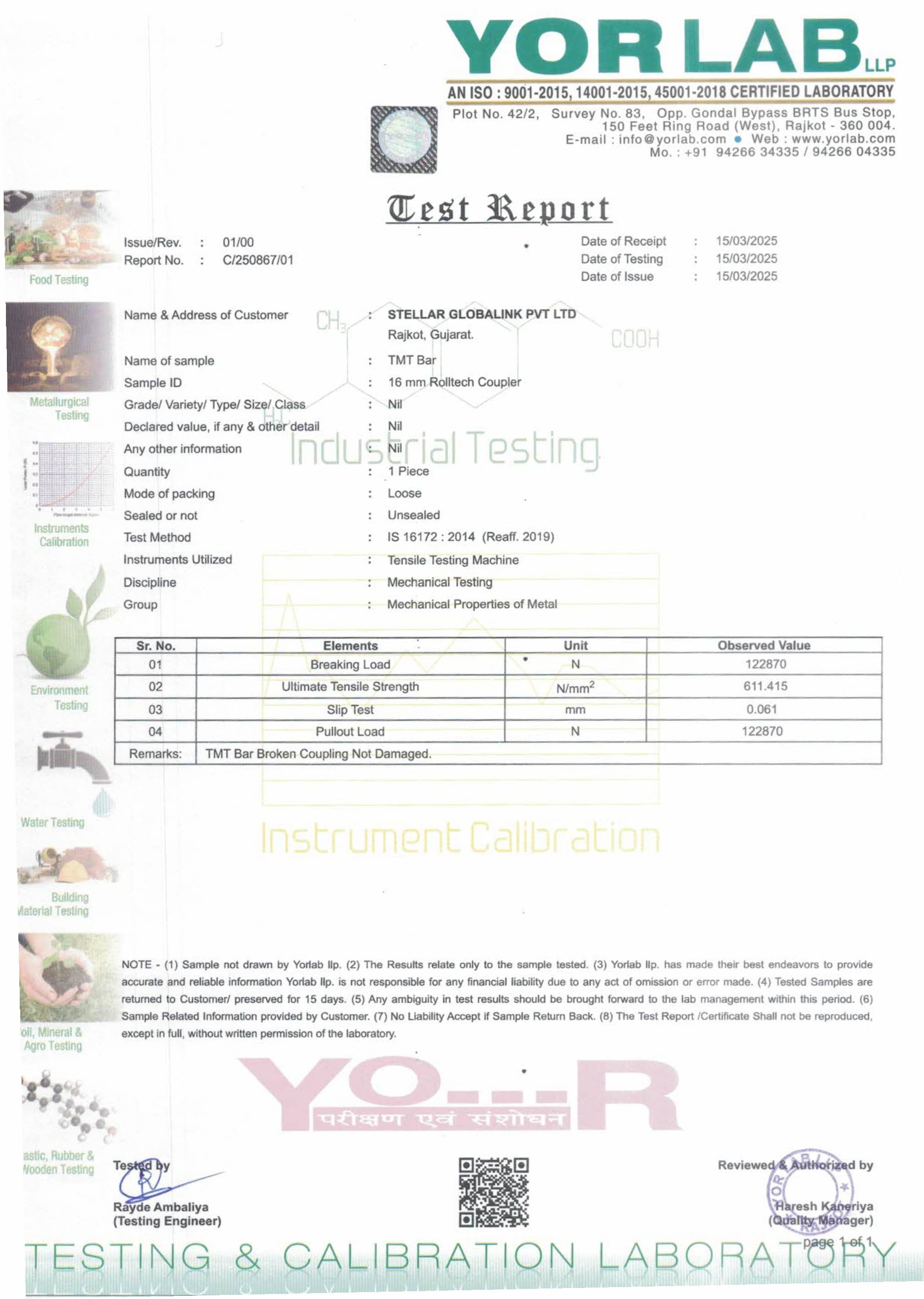

IS 16172:2014

Our couplers are designed to meet the demanding requirements of modern construction projects where traditional lapping is impractical or steel congestion is high.

Perfect for sites where lapping is impractical or steel congestion is high.

All HAVOX couplers undergo comprehensive testing under strict quality control processes to ensure unmatched performance and reliability.

Measures maximum load capacity before failure

Ensures zero slippage under maximum load

Verifies coupler meets or exceeds material specs

Precision measurement of thread compatibility

Let our engineering team prepare a customized solution for your specific requirements.